Recently along with the rapid progress of construction of production and living place and general assembly workyard, the fabrication of Zangmu Grand Bridge on Lhasa-Linzhi railway, the first coating-free weather resistant steel bridge in China and the double-track steel tube arch bridge with the longest span in China, undertaken by CRBBG, is anticipated to start at the end of June.

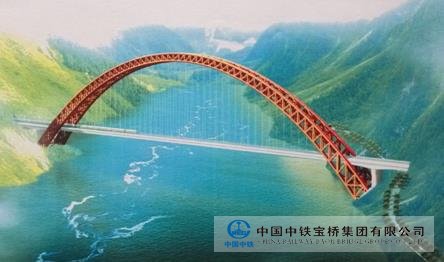

The Zangmu Grand Bridge on Lhase-Linzhi railway is the key landmark project of Sichuan-Tibet railway Lhasa-Linzhi section. The main bridge spans the Brahmaputra River Valley, adopting 430m half-through concrete-filled steel tube arch with a height of 112m, which will be the double-track steel tube arch bridge with the longest span in China. Different from other bridges, this bridge uses Q420qENH and Q345qENH high strength weathering steel and the whole bridge is free from coating, which make it a real sense of the first coating-free weather resistant steel bridge in China and are of great significance to promote the application of weathering steel in bridges in China. CRBBG undertakes manufacturing, segment assembly and field erection of 12,794 tons of steel tube arch in the construction of this bridge.

The three-place fabrication mode is planned for this project, i.e. machining in Linzhi, general assembly in Jiacha and erection at bridge site. The steel plates are transported to Lhasa by train and then transferred to Linzhi by truck; the fabrication of dumbbell-shaped tube panels is completed in Linzhi, and then they are transported to Jiacha by truck for general assembly; finally, they are transported to bridge site to complete segment erection, fine adjustment and circular seam welding. Since several months ago, to make first-phase preparations for the bridge construction, all staff and workers in CRBBG's Lhasa-Linzhi Zangmu Bridge Project Department worked hard on Qinghai-Tibet Plateau of 3,325m above sea level. Facing the severe natural environment of anoxia and mixed rain and snow, they carried forward the spirit of bearing hardship and successfully finished the layout of machining workshop, and now the general assembly field is under construction, which laid solid foundation for the overall start of bridge fabrication at the end of June.

It is known that the exterior surface of coating-free weather resistant bridge will form a beautiful and maintenance-free oxidizing layer when it is exposed in natural environment, which has long-term anticorrosive effect. This bridge has lower life cycle cost, environmental protection signality with paint-free, and saving of maintenance work in rough plateau condition if common coated steel bridge is adopted. The successful construction of it will be another milestone in China's bridge development history as well as play a demonstration role for vigorous promotion of coating-free weather resistant steel bridges.