On April 17, the review meeting for the first fabricated panel of main girder for CB05-G2 Section of Hongkong-Zhuhai-Macao Bridge (HZMB) was held in China Railway Yangzhou Co., Ltd. Mao Xuefeng, Officer of Supervision Office of SB04 Section of HZMB, presided over the meeting. HZMB Administration Steel Office Director Liu Jizhu, Deputy Director Qian Yexiang, Quality Consultant Zhu Shaojiang, CB05 Section Project Headquarters Chief Engineer Zhang Yaojun, and CRBBG General Manager Li Zongmin and CB05-G2 Section Project Manager Cheng Yuhai, were present at the meeting.

The Hongkong-Zhuhai-Macao Bridge, spanning Lingding Ocean at Pearl River estuary, is a large passage over the sea connecting Hongkong, Zhuhai and Macao. The overall length of the bridge is about 35.6 km, which is another great project after Sanxia dam project, Qinghai-Tibet railways, South-to-North water diversion project, and Beijing-Shanghai high speed railways, as well as a traffic project group integrating bridge, island and tunnel with the largest scale, the highest standard and the most challengeability in China and even in the world. In which, CRBBG undertakes fabrication of CB05-G2 Section of the bridge, which include Jiuzhou navigation bridge and non-navigable arch bridge with 23 arches in shoal area. The overall length of bridge is 2,648 meters and total weight of steels is 39,923 tons.

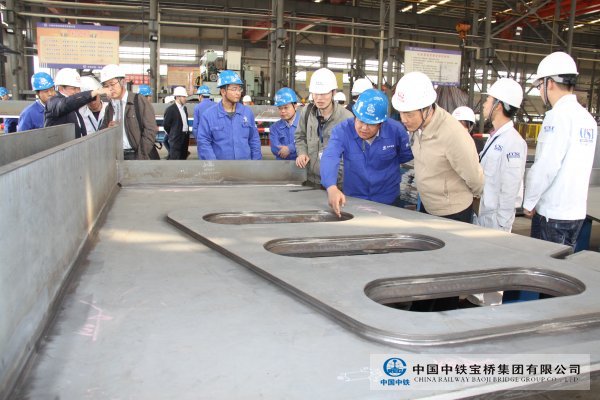

At the meeting, representatives of all units viewed the actual fabricated product, went through the construction data, listened to the "Report on Fabrication of the First Panel of Main Girder for CB05-G2 Section of HZMB" made by CRBBG, "Report on Supervision Work and Quality Evaluation of the First Panel of Main Girder" made by Supervision Office of SB04 Section, "Report on Acceptance Verification of the First Panel of Main Girder" made by Quality Management Consultant, and "Test Report for Acceptance of the First Panel"made by nondestructive testing party, and carried out extensive and deep discussions and exchanges.

The expert team agreed after serious discussion and review that, first, the structure of the first panel selected was typical that covered various types of structure of panels of main girder, and the data provided were complete, detailed and creditable; secondly, various fixtures and lift devices were elaborately designed and used in the fabrication process, and welding with no stack was achieved for panel fabrication, thus meeted the quality requirement of HZMB; thirdly, the first panel fabrication process was scientific and proper, the automatic equipment used was highly intelligent and the equipment precision met quality requirement of product, and the quality inspection result met the requirements of design and relevant specifications. Therefore, CB05-G2 section was agreed to be put into batch production with current automatic equipment and facbrication processes.